Alpha Systems Inc.

Main menu

- Home

- News

-

Products

- Product Summary

- Analytical

- Calibration

- PLC-HMI

- Process Controllers

- Pneumatic Controls

- Humidity Instruments

- Level Measurement

- Process Equipment

- Valves and Fittings

- Service

- Contact

-

Shop Online

- PIE Calibrators

- Martel Calibrators

- Beta Calibrators

- Powersight Meters

- Gammatech Computers

- Unitronics PLC

- Access Online Store

Numem Filtration

Introduction

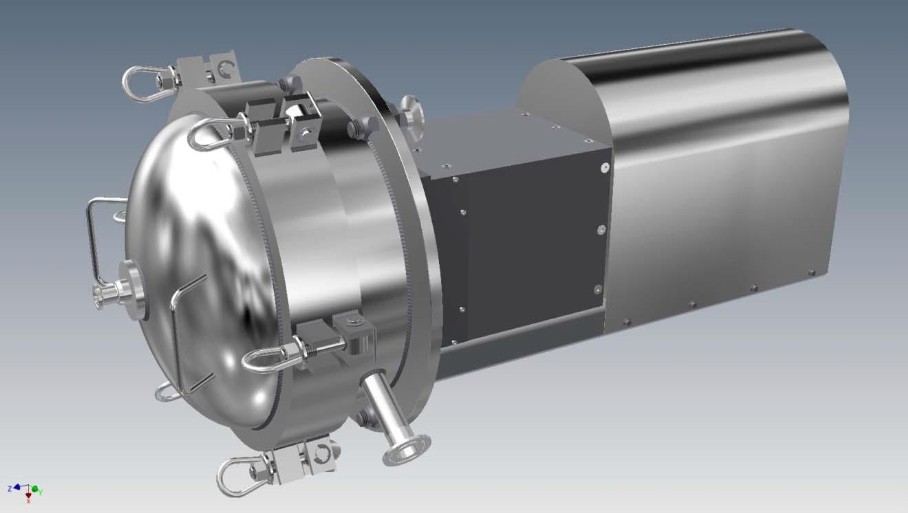

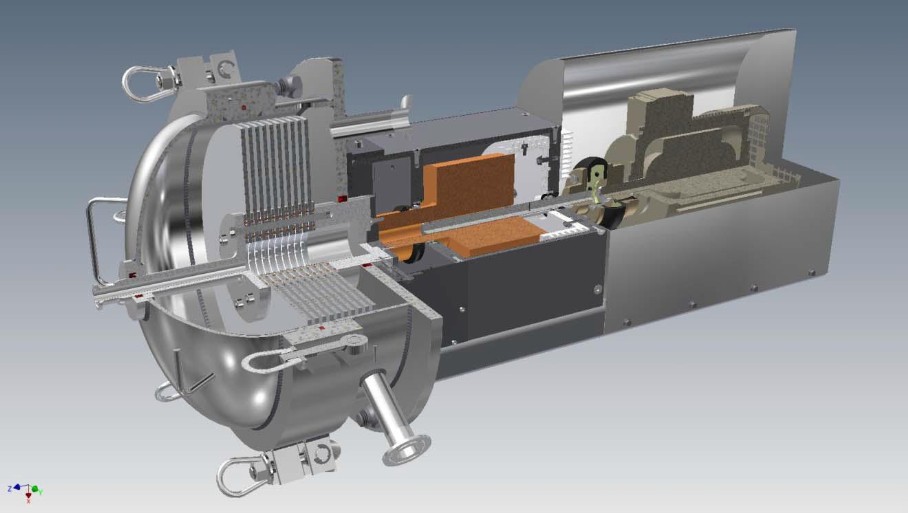

Overview of the Complete System

The NUMEM OSCILLATION DRIVER is pending patent, membrane-

technology that provides the ability to accomplish separations that are not efficiently or effectively possible with conventional cross flow membrane systems.

The NUMEM TECHNOLOGY [N.T.] efficiently generates mechanical shear with

oscillation, rather than by pumping high volumes of re-

membrane, as is typical in a cross flow systems. The oscillation disc filter stack membrane surface with a spacer mounting on standard housing.

The surface shear created by the NUMEM OSCILLATION process prevents fouling of the membrane and allows the system to produce retentate streams with high-

concentrations, that is, desired materials penetrate the membrane at a high flow rate.

N.T.filtration is a pressure driven filtration technique in which a solution is forced through a porous membrane. Some of the dissolved solids are held back because their molecular size or combine molecular is too large to allow them to pass through, the size depending upon membranes used and the frequency of the oscillation. This is important for critical separations during both production processing, and especially during membrane cleaning and CIP (clean-

Benefits of the NUMEM System

The N.T. provides new opportunities for efficient and effective separations, with up to 22 times the shear with far less energy consumption than conventional cross flow systems.

The enhanced ability to clean the N.T.System allows for quick and efficient recovery of the membrane both during processing and for subsequent production runs.

Since all the oscillation energy is focused on the membrane surface, very little energy is lost to the bulk fluid, thus the N.T. low-

Low‐solid applications that are typically handled by cross flow systems.

High‐solid applications, which cannot be handled by static cross flow systems (and are usually handled by centrifuges and filtration systems that use a filter aid pre‐coat such as rotary vacuum filters).

High pressure application, which are typically handled by filter press system.

High temperature that are handled by evaporator.

Membrane Types Used

The system utilizes microporous membranes such as:

1-

2-

3-

4-

Most N.T. applications use